In the realm of manufacturing and industrial processes, precision is paramount. One of the indispensable tools that contribute significantly to achieving this precision is grinding machines and machinery. These versatile devices play a crucial role in shaping and finishing various materials with unparalleled accuracy. Let’s delve into the world of grinding machines to understand their significance and diverse applications.

Precision Redefined: The Basics of Grinding Machines

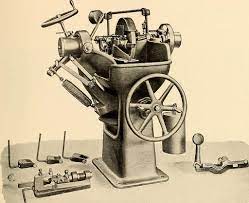

Grinding machines are mechanical devices designed to remove excess material from workpieces to attain the desired shape, finish, or dimensional accuracy. They utilize abrasive wheels as cutting tools, ensuring precision and efficiency in material removal. These machines find applications in a myriad of industries, ranging from automotive and aerospace to medical and general manufacturing.

Types of Grinding Machines

- Surface Grinding Machines:

- Ideal for flat surfaces, these machines use abrasive wheels to remove material from the workpiece’s surface, ensuring a smooth and precise finish.

- Cylindrical Grinding Machines:

- Tailored for cylindrical or rod-like workpieces, these machines excel in achieving high-precision cylindrical shapes with tight tolerances.

- Tool and Cutter Grinding Machines:

- Dedicated to sharpening and reconditioning cutting tools, these machines enhance tool performance, prolonging their lifespan and ensuring consistent quality.

- Centerless Grinding Machines:

- Employed for outer diameter grinding, centerless machines excel in producing cylindrical workpieces without the need for a centering mechanism.

The Advantages of Grinding Machinery

- Precision and Accuracy:

- Grinding machines offer unparalleled precision, ensuring tight tolerances and high-quality finishes on machined parts.

- Versatility:

- From metal and ceramics to composites and plastics, grinding machinery can handle a wide range of materials, making them versatile solutions for diverse industries.

- Efficiency:

- With advancements in technology, modern grinding machines boast automation features, reducing manual labor and enhancing overall efficiency in production processes.

- Cost-Effectiveness:

- Grinding allows for the reuse of materials by removing imperfections or excess material, contributing to cost savings in the manufacturing process.

Emerging Trends in Grinding Technology

- Digitalization and Industry 4.0 Integration:

- Grinding machines are becoming increasingly interconnected with digital systems, enabling real-time monitoring, data analytics, and predictive maintenance.

- Environmental Sustainability:

- Manufacturers are adopting eco-friendly grinding practices, incorporating technologies that minimize waste and energy consumption.

In conclusion, grinding machines and machinery stand as indispensable pillars in the manufacturing landscape, ensuring precision, versatility, and efficiency in material shaping and finishing. As technology continues to advance, these essential tools evolve, promising even greater levels of accuracy and sustainability for the industries they serve.

Check out Sparx Machine Tools for more information.